SEARCH

— 葡萄酒 | 威士忌 | 白兰地 | 啤酒 —

— 葡萄酒 | 威士忌 | 白兰地 | 啤酒 —

The unmanned mining truck market in open-pit coal mines represents one of the most exciting developments in industrial automation. These autonomous vehicles are fundamentally changing how we approach mining operations through advanced 5G remote control technology.

By deploying unmanned trucks with 5G remote control capabilities in hazardous environments, we’re finally taking people out of harm’s way. These machines come equipped with cutting-edge sensors and remote sensing technology that allow them to detect and navigate around obstacles with remarkable precision, even in the most challenging mining conditions. The result? Fewer workplace accidents and, most importantly, fewer lives at risk.

From a business perspective, the economics are compelling. Unmanned trucks with 5G remote control operate 24/7 without needing shift changes or rest breaks. This means dramatically improved transportation efficiency and significant cost savings on labor. We’re talking about a fundamental shift in how mines can optimize their operations.

What really impresses is the intelligence of these systems. Using advanced navigation and route-planning algorithms, these trucks follow predetermined paths with pinpoint accuracy. They communicate in real-time with central control systems via 5G remote control networks, allowing them to adjust routes on the fly based on dispatch instructions. It’s this kind of coordination and responsiveness that makes the whole operation work seamlessly.

Every unmanned truck is essentially a mobile data collection center, continuously gathering information on payload, temperature, operating status, and more. This data becomes invaluable for predictive maintenance and optimizing equipment lifecycles through the 5G remote control platform, helping extend the useful life of these substantial investments.

Today’s most advanced unmanned trucks have automated loading and unloading capabilities, pushing efficiency to new heights while maintaining strict safety standards. As the technology matures, 5G remote control systems are enabling even higher levels of automation and intelligence.

Each unmanned vehicle is loaded with impressive technology that works together through 5G remote control networks:

High-precision positioning and navigation systems, high-definition image capture, dynamic obstacle detection and avoidance, and LiDAR technology all communicate through 5G networks. These trucks maintain constant communication with intelligent dispatch management platforms, enabling remote task assignment and coordination.

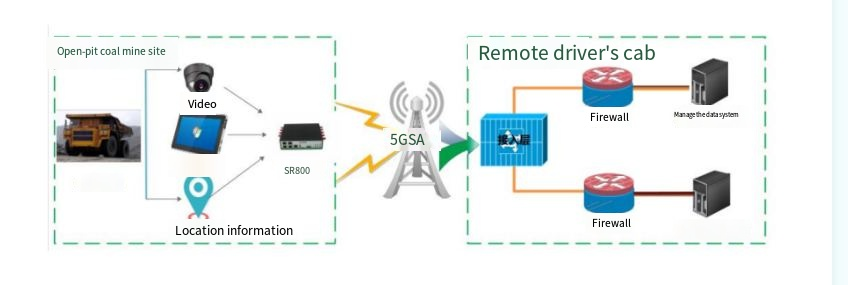

[Image suggestion: Insert technical diagram of the 5G remote control system architecture]

The dedicated 5G network makes both remote driving and autonomous driving possible. The intelligent management system handles remote diagnostics, software updates, and maintenance – all from a distance through 5G remote control capabilities. This is what’s driving the smart transformation of open-pit coal mines.

Robot controllers, 3D LiDAR, cameras, positioning systems, recognition systems, and more

Industrial-grade 5G routers with multiple Ethernet ports solve the connectivity challenge

Intelligent dispatch system: Monitor vehicle trajectories and status in real-time to ensure safe operations

Industrial-grade 5G routers with multiple Ethernet ports provide the backbone for 5G remote control operations, solving complex connectivity challenges in mining environments.

The intelligent dispatch system enables operators to monitor vehicle trajectories and status in real-time through the 5G remote control interface, ensuring safe operations across the entire fleet.

Mo