SEARCH

— 葡萄酒 | 威士忌 | 白兰地 | 啤酒 —

— 葡萄酒 | 威士忌 | 白兰地 | 啤酒 —

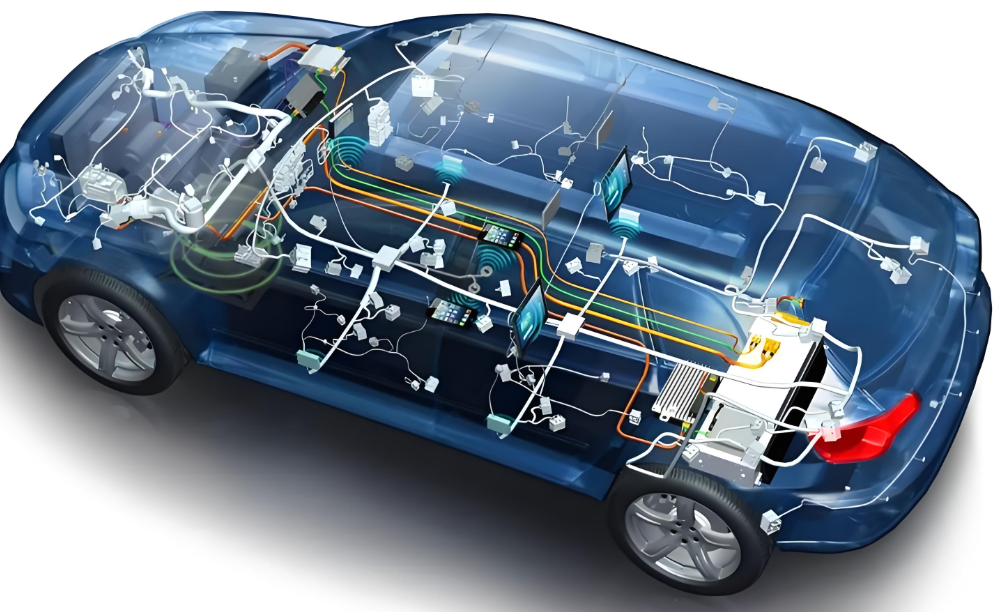

Hello everyone, I’m an engineer from key-iot. Recently, while working on intelligent connected vehicle projects, I noticed that more and more OEMs and Tier 1 suppliers are discussing the “Automotive Ethernet Protocol.” In fact, in-vehicle Ethernet is no longer a new concept, but its protocol system is quite different from traditional IT Ethernet. Today, let’s talk about what the automotive Ethernet protocol is and why it’s becoming the “new infrastructure” for smart vehicles.

Simply put, the Automotive Ethernet Protocol is a family of Ethernet protocols specifically designed for in-vehicle communication. It’s not a single protocol, but a complete system spanning from the physical layer to the application layer, aiming to enable efficient and reliable interconnection among various electronic control units (ECUs), sensors, cameras, and other devices inside the car.Why not just use traditional CAN, LIN, or FlexRay? Because these legacy buses have limited bandwidth and can no longer meet the data rate and real-time requirements of new applications like autonomous driving, smart cockpits, and in-car entertainment. Ethernet offers high bandwidth, low cost, and strong scalability, making it the preferred choice for the next generation of in-vehicle networks.

When discussing protocols, we can’t avoid the OSI seven-layer model. The automotive Ethernet protocol stack is basically designed along these lines, but each layer is specially optimized for automotive scenarios.

1. Physical Layer (PHY)The physical layer of automotive Ethernet is quite different from traditional Ethernet. The most typical standards are 100BASE-T1, 1000BASE-T1, and 10BASE-T1S. These standards all use single-pair unshielded twisted pair (Single Pair Ethernet), support full-duplex communication, have strong anti-interference capabilities, and are lightweight—perfect for the complex automotive environment.The physical layer mainly defines hardware interfaces, signal encoding, data-to-signal conversion and transmission, as well as master-slave mode confirmation. For example, 100BASE-T1 can achieve 100Mbps full-duplex communication on a single pair of wires, greatly simplifying in-vehicle wiring.

2. Data Link Layer (MAC)The data link layer is responsible for frame encapsulation, addressing, and error detection. Automotive Ethernet introduces VLAN (Virtual LAN) technology at this layer, which can divide a physical network into multiple logical broadcast domains, isolate broadcast storms, and improve network quality. For example, the powertrain system and entertainment system can belong to different VLANs, not interfering with each other, making the network more stable.

3. Network LayerThe network layer of automotive Ethernet mainly uses ARP and IP protocols. ARP handles the mapping between IP addresses and MAC addresses, while the IP protocol is responsible for packet addressing and forwarding. IPv4 is mainstream, but IPv6 is gradually being adopted. CIDR (Classless Inter-Domain Routing) allows for more flexible subnetting, making large-scale node management easier.

4. Transport LayerThe transport layer supports protocols like ICMP, UDP, and TCP. ICMP is mainly used for network testing (such as PING), while UDP and TCP are suitable for scenarios with different real-time and reliability requirements. For example, video streams and radar data use UDP, while diagnostics and calibration use TCP.5. Application LayerThe application layer protocols are very rich, mainly including:

1. High Bandwidth, Low LatencyTraditional CAN bus bandwidth tops out at 1Mbps, FlexRay at 10Mbps, while automotive Ethernet easily reaches hundreds of Mbps or even Gbps, meeting the massive data transmission needs of HD cameras, radars, and LiDAR.2. Flexible Expansion and Easy IntegrationEthernet is an open standard with good device compatibility and is easy to interface with IT systems. Technologies like VLAN and TSN make network topology more flexible, adapting to different vehicle models and functional requirements.**3Below is the full English translation of the original text about the “Automotive Ethernet Protocol,” written in the style of a Key-IoT employee for a forum like Enshan Wireless Forum.

Hello everyone, I’m an engineer at Key-IoT. Recently, while working on projects related to intelligent connected vehicles, I noticed that more and more automakers and Tier 1 suppliers are discussing the “Automotive Ethernet Protocol.” Although automotive Ethernet is not a new concept, its protocol system is quite different from traditional IT Ethernet. Today, I’d like to share with you what the Automotive Ethernet Protocol is and why it has become the “new infrastructure” for smart vehicles.

In simple terms, the Automotive Ethernet Protocol is a set of Ethernet protocols specifically designed for in-vehicle communication. It is not a single protocol but a comprehensive system that spans from the physical layer to the application layer, aiming to enable efficient and reliable interconnection between various in-vehicle devices, such as electronic control units (ECUs), sensors, and cameras.Why not use traditional protocols like CAN, LIN, or FlexRay? The reason is that these traditional bus systems have limited bandwidth and can no longer meet the data rate and real-time requirements of new applications like autonomous driving, smart cockpits, and in-car entertainment. Ethernet, with its high bandwidth, low cost, and scalability, has naturally become the preferred choice for the next generation of in-vehicle networks.

When discussing protocols, we can’t avoid the OSI seven-layer model. The Automotive Ethernet Protocol stack is essentially designed based on this model, but each layer has been specially optimized for automotive scenarios.1. Physical Layer (PHY)

The physical layer of automotive Ethernet is quite different from traditional Ethernet. The most typical standards are 100BASE-T1, 1000BASE-T1, and 10BASE-T1S. These standards use single-pair unshielded twisted pair (Single Pair Ethernet), support full-duplex communication, have strong anti-interference capabilities, and are lightweight, making them suitable for the complex automotive environment.The physical layer mainly defines hardware interfaces, signal encoding, data-to-signal conversion, and master-slave mode confirmation. For example, 100BASE-T1 can achieve 100 Mbps full-duplex communication over a single pair of cables, significantly simplifying in-vehicle wiring.

2. Data Link Layer (MAC)

The data link layer is responsible for frame encapsulation, addressing, and error detection. Automotive Ethernet introduces VLAN (Virtual Local Area Network) technology at this layer, which can divide a physical network into multiple logical broadcast domains, isolate broadcast storms, and improve network quality. For instance, the powertrain system and entertainment system can belong to different VLANs, ensuring network stability by preventing interference.

3. Network Layer

The network layer of automotive Ethernet primarily uses ARP and IP protocols. ARP handles the mapping between IP addresses and MAC addresses, while the IP protocol is responsible for packet addressing and forwarding. IPv4 is the mainstream choice, but IPv6 is gradually being adopted. CIDR (Classless Inter-Domain Routing) allows for more flexible subnetting, making it easier to manage large-scale nodes.

4. Transport Layer

The transport layer supports protocols like ICMP, UDP, and TCP. ICMP is mainly used for network testing (e.g., PING), while UDP and TCP are used for scenarios with different requirements for real-time performance and reliability. For example, video streams and radar data use UDP, while diagnostics and calibration use TCP.5. Application Layer

The application layer includes a variety of protocols, such as:

1. High Bandwidth and Low Latency

Traditional CAN bus bandwidth is capped at 1 Mbps, and FlexRay only reaches 10 Mbps. In contrast, automotive Ethernet easily achieves hundreds of Mbps or even Gbps, meeting the demands of high-definition cameras, radar, and LiDAR for large data transmission.

2. Flexible Scalability and Easy Integration

Ethernet is an open standard with excellent device compatibility, making it easy to integrate with IT systems. Technologies like VLAN and TSN allow for more flexible network topologies, adapting to different vehicle models and functional requirements.

3. Real-Time and Deterministic Communication

Through extensions like AVB (Audio Video Bridging) and TSN (Time-Sensitive Networking), automotive Ethernet can achieve millisecond- or even microsecond-level real-time communication, meeting the stringent latency requirements of autonomous driving and chassis control.

4. Cost and Weight Advantages

The single-pair cable design significantly reduces wiring costs and weight, especially for electric and smart vehicles that demand lightweight solutions.

Mo