Industrial router project application (4g+5g industrial router project introduction)

419Industrial router

View detailsSearch the whole station 4G Industrial Router Products

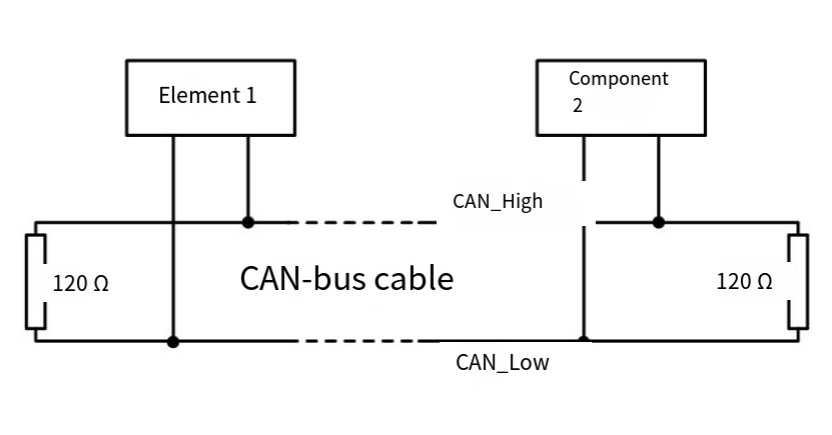

CANBus can acquire a wealth of information from field devices, better meeting the information integration requirements of factory automation and industrial systems. As a digital communication network, CANBus enables the transmission of device status, fault, and parameter information. In addition to remote control, CANBus communication systems can also perform remote parameterization.

CANBus communication systems are open, allowing engineers to integrate the required control technologies and process workflows into the communication system. Moreover, products from different manufacturers that adhere to the same CANBus communication standards possess interoperability, interchangeability, and ease of integration.

Communication systems based on CAN bus utilize serial connections instead of one-to-one I/O wiring, reducing the wiring between nodes for large-scale I/O systems. Furthermore, CANBus communication systems feature online fault diagnosis, alarm, and recording functions, enabling remote monitoring and data modification of field devices, thus enhancing system maintainability.

For large-scale and widely distributed I/O systems, a significant amount of wiring costs can be eliminated, reducing overall project costs.

6G technology research is not about who is first, but about which country can contribute more technological solutions beneficial to social development.

View detailsWith its advantages of openness, high bandwidth, and scalability, Ethernet has become the mainstream choice for industrial networks.

View detailsHey everyone, I'm Old Li, a technician who has been working in the industrial automation field for many years. Today, I want to share with you about my old friend - the RS485 communication protocol. It's like the bond that connects various industr...

View details