Hello to all forum friends! I’m Old Gao from KEY-IOT, and after years in network technology, I work daily with various industrial control and IoT devices. Today I’d like to share some practical insights and our team’s hands-on experience with SIM CPE, hoping it will be helpful to you all.

I. What is SIM CPE?

SIM CPE (Customer Premises Equipment) is essentially a network terminal device with a SIM card slot that enables internet access via cellular networks. Unlike traditional CPE, SIM CPE provides network connectivity through mobile networks (4G/5G) rather than fixed broadband, making it particularly suitable for scenarios where fixed networks can’t reach or where backup links are needed.

From our actual deployment experience, SIM CPE has become standard equipment for industrial internet, smart cities, remote monitoring, and other applications. For one chemical plant customer with a complex environment unsuitable for wiring, we replaced the original wired network solution with SIM CPE, not only saving significant wiring costs but also improving network stability.

II. Advantages of SIM CPE

As a KEY-IOT technical engineer, I’ve seen too many cases of project delays due to choosing the wrong equipment. These advantages are key reasons why we recommend SIM CPE to our customers:

- Extremely simple installation and deployment: Insert card, power up, auto-connect—no professional personnel required, reducing installation time by 90%.

- Stable and reliable connection: Compared to ordinary WiFi routers, industrial-grade SIM CPE uses high-quality components with Mean Time Between Failures (MTBF) typically exceeding 100,000 hours.

- Extensive coverage: Deployable wherever there’s mobile signal, especially suitable for remote area monitoring systems.

- Dual SIM redundancy design: Most SIM CPEs support dual SIM backup, automatically switching to the backup SIM when the primary one encounters issues, ensuring business continuity.

- VPN encryption support: Built-in various VPN protocols for direct encrypted data transmission, meeting security-sensitive scenario requirements.

We once deployed nearly a hundred SIM CPE devices for a cross-provincial chain supermarket, replacing their original home routers. After the switch, network failure rates decreased by 87% and maintenance costs were reduced by more than half. Store managers reported: “If we had known about this equipment earlier, we wouldn’t have needed to call customer service every day!”

III. Key Indicators When Purchasing SIM CPE

When selecting SIM CPE, I recommend that forum friends focus on these parameters:

- Network support: Whether it supports 5G/4G full-network compatibility, RedCap, and other new technologies

- Interface richness: Industrial applications often need RS232/RS485 and other serial ports

- Operating temperature: Ordinary devices 0-40°C, industrial grade typically -35-75°C

- Power supply method: Whether it supports wide voltage input (e.g., 9-36V DC)

- Management features: Whether it supports remote management platforms

- Protection rating: IP30 or above to handle harsh environments

Recently when selecting models, I strongly recommend considering SIM CPE products that support domestic chips. They’re not only more price competitive but also easier to gain project support in certain specialized industries.

IV. Actual Testing Case Sharing

Last year, our team conducted detailed tests on 10 mainstream SIM CPE models in the market, with comprehensive evaluations of signal reception capability, network stability, VPN performance, power consumption, and more. Results showed that devices using Qualcomm X55/X60 chips perform excellently in 5G scenarios but have relatively high power consumption, while MediaTek chip solutions offer better cost-effectiveness in 4G scenarios.

It’s particularly worth mentioning that when base stations are heavily loaded, SIM CPEs supporting dual-antenna 4×4 MIMO technology can still maintain stable connections in weak signal areas, with upload speeds more than 40% higher than ordinary devices.

V. Technical Details and Configuration Optimization of SIM CPE

As a KEY-IOT technician, I want to share some deeper technical content that might help those of you who enjoy tinkering with technology.

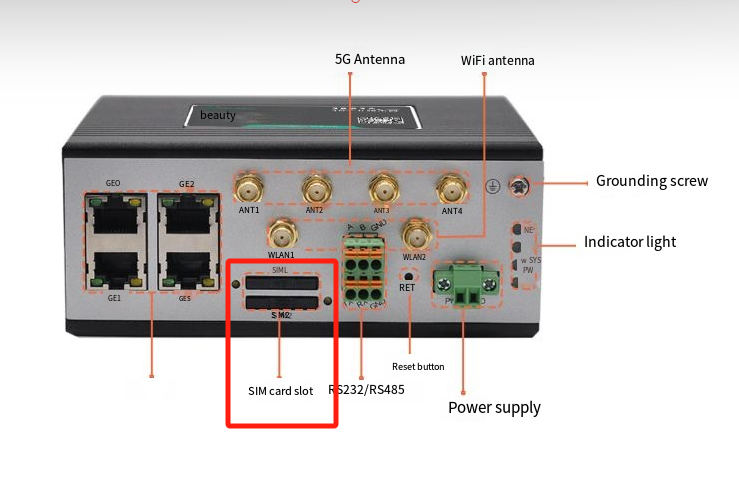

Our latest developed SR820 5G CPE is a highly integrated industrial router with these core features:

- Hardware configuration: 512MB RAM, 4GB EMMC flash storage

- Network support: 5G NR/RedCap networks, supporting SA/NSA dual-mode

- Rich interfaces: 4 gigabit LAN ports (1 can be repurposed as WAN), 1 RS232, 1 RS485

- Dual SIM design: Supports 2 physical SIM card slots + eSIM

- Operating temperature: -35°C to +75°C, far exceeding ordinary CPE

- Power control: Only 300-350mA@12V in standby, 400-600mA@12V when running

- Protection rating: IP30 metal casing, sturdy and durable

5.2 Network Optimization Tips

In actual SIM CPE deployments, I’ve found many forum friends encountering network instability issues. Here are some optimization methods I commonly use:

1. Frequency Band Locking Technology The SR820 supports 5G frequency band locking, which can lock onto the band with the best signal in complex signal areas:

# Example: Lock n41/n78 bands

at+qnwlock="common/4g",0

at+qnwlock="common/5g",0,"n41 n78"

2. Antenna Position Optimization AT commands can be used to check signal quality in different directions:

When RSRP value is greater than -105dbm, it indicates good signal. My suggestion is: first use a mobile phone to test and find the optimal position, then fix the antenna.

3. APN Setting Tips Public network SIM cards and private network SIM cards have different APN settings, for example:

# Public network card

at+cgdcont=1,"IP","cmnet"

# Private network card (using a power industry private network as an example)

at+cgdcont=1,"IP","dl.myapn.com"

5.3 Advanced Configuration Solutions

1. Dual Link Redundancy Solution The SR820 supports wired+5G dual link redundancy, configuration method:

# Enable link detection

link_detection enable

# Set primary and backup links

primary_link eth0

backup_link wwan0

# Set detection targets

detection_target 114.114.114.114 8.8.8.8

# Set switching threshold

failover_threshold 5

2. Industrial Protocol Transparent Transmission Configuration The SR820 has built-in DTU functionality, and its RS485 interface can directly collect PLC data:

# Enable Modbus RTU to TCP bridge

dtu_mode modbus_bridge

serial_params 9600,8,1,none

server_addr 192.168.1.100

server_port 502

3. VPN Tunnel Configuration Most of our industrial clients use IPsec VPN to ensure data security:

# IPsec configuration example

ipsec_type esp

ipsec_auth sha256

ipsec_encrypt aes256

ipsec_mode tunnel

local_subnet 192.168.1.0/24

remote_subnet 10.0.0.0/24

psk_key "YourStrongPreSharedKey"

5.4 Common Troubleshooting

- Strong signal but slow speed: Check if connected to the correct network mode (NSA/SA), performance is better in SA mode

- Frequent disconnections: Check if the keepalive feature is enabled, recommend setting a 30-second heartbeat

- VPN connection failure: Check if NAT-T traversal option is enabled in NAT environment

- Device overheating: In industrial scenarios, recommend adding heatsinks and setting automatic temperature-controlled frequency reduction

Conclusion

As a key device in industrial IoT, SIM CPE is not just a simple network terminal but a bridge connecting various industrial equipment. Choosing the right product and correct configuration method is critical to project success.

I hope my sharing helps all forum friends. If you have questions, please leave comments below. I will continue sharing more practical experience in the industrial networking field!